An additional item and with several zeros on the right is part of the budgets of the civil works that are executed or projected at present, it is the automation of buildings and their internal resources. Latin America has not wanted to be left behind and has entered the successful and practical boom of technological implementation that makes any place "smart".

An additional item and with several zeros on the right is part of the budgets of the civil works that are executed or projected at present, it is the automation of buildings and their internal resources. Latin America has not wanted to be left behind and has entered the successful and practical boom of technological implementation that makes any place "smart".

by: María Cecilia Hernández

Imposing automated buildings stand on the streets of major Latin American cities, Bogota, Medellin, Lima, Panama City, Buenos Aires, Rio de Janeiro and many others already have excellent examples of what a smart space is.

It is not a basic matter of fashion or simple whim. A person who intends to invest his money in a civil work, whether for commercial, industrial or residential purposes, knows perfectly well that if he seeks to have total and centralized control of the building and its internal resources, he must considerably increase his investment in technology and equipment necessary for that purpose.

However, it should also be known that over the years the investor achieves a staggered saving on account of the effective, predictive, reactive and automatic management of each corner of the place.

In an intelligent building, administration and management does not require a large number of employees to perform the same functions that a single machine, or various networked equipment, achieve perfectly. As a consequence, this translates into a significant decrease in costs.

Automating a building also allows you to have valuable information in an orderly and centralized way about the dynamics of the establishment, which ultimately concludes in having important data at hand to propose market and security strategies. Likewise, the use of technology reduces the chances of accidents and risks and finally, automation provides the opportunity to protect the environment.

ACR LATINOAMÉRICA consulted with different professionals from renowned companies belonging to the automation industry about the proposals for intelligent spaces that they consider most relevant. Here we will present five of the most important projects that were built or are in execution in the center and south of the American continent.

Controlled cooling

Supermarkets World – Rio de Janeiro – Brazil, automation executed by RGT Inginiería through Full Gauge Controls controllers.

In order to offer maximum quality and durability of the products to the supermarket chain Mundial de Rio de Janeiro, the Brazilian company RGT Ingeniería, a reference in projects, refrigeration works and maintenance of systems, implemented an ammonia-based refrigeration system with a total capacity of 2,490 kW of cooling and Full Gauge Controls and Danfoss controllers for automation.

Ammonia, as is well known in this market, has multiple advantages associated with the protection of the environment, does not destroy the ozone layer and does not contribute to the greenhouse effect that triggers the current problem of global warming. According to experts in the field of refrigeration, this substance has better results, is efficient and economical.

Mauricio Sendim Vieira, Engineer of RGT Ingeniería, who participated in the installation of the refrigeration system for the World Supermarkets, indicates that "the proposal implemented there, is completely automatic and capable of supervising the liquid separation regimes, which guarantees a correct operation within the pressure and temperature ranges previously projected through the level control. An automatic control is responsible for grading the cold chamber and the solenoid valves and special sensors guarantee the constant temperature level. All the main functions of the system are managed through a computer in which a PLC (Programmable Logic Controller) was installed that has visual alarm of critical functions".

An important aspect of the project was the installation of frequency converters to power the compressors. This represents a huge energy saving. The compressors are driven by asynchronous motors of 175 and 400 hp e and the use of converters provides savings of around 25% on this plot.

Wide reach

Avianca Building – Santafé de Bogotá – Colombia, automation executed by Johnson Controls.

After the central building of the first Colombian airline, Avianca, suffered a serious fire in 1973 that destroyed the entire building and left a tragic balance of loss of life and injured people, the idea of building a safe and automated structure never left the minds of the owners of aeronautics.

This is how in 2009 the new Avianca building was inaugurated, a ten-story construction in 13,800 square meters, near the Gran Estación shopping center, on Calle 26 with Carrera 69 in the Colombian capital. The firm Ospinas y Cía. S.A. was responsible for the work. And Johnson Controls was the company in charge of the manufacture and integration of technology capable of making the structure an intelligent and eco-friendly building.

This is how Erica Bernal, representative of the integrating company, explains: "The Avianca tower was born as an office project with a basic control system. However, during the process the scope of the requirement was growing, the protection specifications increased and with it the technology had to be more sophisticated and the amount of equipment had to grow. In this building the access control is through the palm of the hand, which implies the use of a more qualified and expensive system, in addition there were particular specifications on the differentiation between visitors and employees, including the control of parking lots and the systematization of charges for that same concept ".

The integration proposal also considered the control of the building's basic services, lighting, power plants, variable air conditioning, closed circuit television and other monitorable signals. "Everything is managed through our integration platform called Metasys," Bernal explains. The project had an approximate execution duration of one year.

Countries working together

Residential complex and hotel Trump Ocean Club – Punta Pacifica – Panama, integration executed by EBC International Ltda.

This is the first investment project in Central America made by the Trump Organization, of the renowned businessman Donald Trump. A 68-story tower that will be the third tallest skyscraper in Panama, where there will be a residential area and a hotel. For the electronic security proposal, the Colombian integrating firm EBC International Ltda. was hired. According to Gustavo Muñoz, one of its representatives, the system contains fire and smoke detection and alarm, a fully digital video network with cameras and IP domes, lighting control and supervision of basic services.

The expert explains that "the system also has an HVAC (Heating, Ventilating and Air Conditioning) control and integration equipment that works through a modbus network and has programmable logic controllers. It also has a monitoring and integration system for equipment such as Ups, plants, substation through protocols such as LonWorks and BACnet. The system is fully integrated into a server, and all controllers are connected via the Ethernet network which is dedicated exclusively to the operation of this integration." The objective is to have a Building Automation Solutions (BAS) or a Building Management Systems (BMS) with all the required equipment, and this includes the management of energy and its pricing.

Green architecture

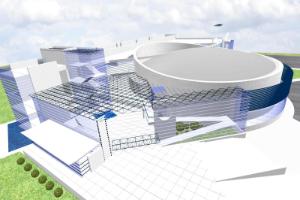

Platinum Plaza Buildings Towers 1 and 2 – Lima – Peru. Integration executed by Controlmatic

In 20,000 square meters two towers of 15 floors are erected throughout the center of San Isidro, of the Peruvian capital. The construction, recently inaugurated, is the Platinum Plaza office real estate project, which has as its fundamental premise the construction and maintenance based on the care of the environment and the use of energy and water.

Constructores Interamericanos S.A.C. It was in charge of the execution of the work and together with the Inter-American Bank of Finance are the owners of the project. The process of integrating electronic security, access control and automation was carried out by the company Controlmatic. The vast majority of the equipment implemented was from the Honeywell brand.

Andrés Fernández, representative for the Latin American Andean Region of the company Honeywell, affirms that the design of the project is friendly to the environment, since the distribution of the facilities allow an optimal use of natural lighting, which favors the saving of electrical energy. The proposal has a water system that reduces the disposal of waste into the sea. In the parking lots, carbon monoxide extractors were installed that also control the polluting gases, this reduces the risk that users may have due to direct contact with harmful emanations.

In the construction, sensors were also installed (in taps and toilets) for the management of drinking water and drainage, this allows a more rational use of water and reduces discharges to the sewage system. With regard to energy, curtain walls were built with a thermopanel (double-layer insulated glass, with vacuum between them), to reduce the use or intensity of air conditioning. It also has high efficiency lamps that reduce energy consumption.

An automated oil refinery

Centralized control building of the Ecopetrol refinery – Barrancabermeja – Colombia, Integration executed by EBC International Ltda.

For more than ten years, the integrating firm EBC International Ltda., has been intervening in the technological issue to the Ecopetrol refinery located in the town of Barrancabermeja. It is in this way that at present this headquarters of the most important oil company in Colombia, has more than ten control rooms that manage various services and processes of that company, these have been called "satellite rooms" or EBI (Enterprise Building Integrator) which by itself already means a whole integration system independent of the rest.

"This project, which began in August 2010 and will end in a year, will have as its fundamental objective to communicate each of these satellite rooms through an architecture called DSA (Distributed Server Architecture) in which our centralized control room (the main one and that is the one that is currently under design) will be able to see priority alarms and capture all the signals of each satellite room", explains Oscar Silva, representative of the integrating firm.

This main room is a three-story, 8,000-square-meter construction located in the production area of the Ecopetrol refinery. It will be a system operated by multiple people through roles and profiles, for example, it will be possible to control the maintenance area, the security area, the operation of the plant, among others, independently but with a single system.

"It is not the same to have three stations that fulfill different functions separately, than to have a single one that can do everything; it saves operating costs and it is possible to have the information in a single database. So far we are beginning to see the value that is generated with an automation and control system, but there are pioneering companies that are marking the issue. I think in about five years it's going to be a requirement and everyone is going to want to have this type of technology," Silva said.