Digital controls are the key component of an automation project and their proper functioning depends on achieving significant savings in energy consumption and improving comfort and safety conditions.

Digital controls are the key component of an automation project and their proper functioning depends on achieving significant savings in energy consumption and improving comfort and safety conditions.

by: Vanesa Restrepo

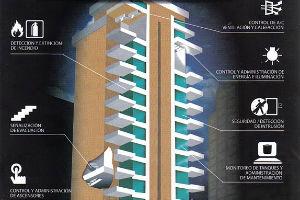

Advances in technology have allowed that today when thinking about the construction or remodeling of a commercial building, offices or a hotel, automation is the main axis. The reason is simple: automating allows direct control over each of the aspects of the building's AC installations, which makes it possible to detect faults, save energy and optimize the use of comfort equipment, just to mention a few.

To this is added the possibility of integrating air conditioning and ventilation systems with other tools such as lighting, fire alarms and CCTV systems, with a consequent improvement in the comfort and safety of work areas or room.

Automating equipment from different manufacturers or for different purposes has become, today, the goal of any installer. Fortunately for them, the industry has had BACnet since 1995, an open communication protocol developed by ASHRAE in order to facilitate and massify building automation.

With the arrival of this protocol, which as we said is free, allowed substantial cost savings in the process of system integration. Until before BACnet, each manufacturer developed its equipment, and that same or similar company created intermediate devices, known as bridges, to allow the communication of the systems. Making a simile, we could say that each team spoke a different language, and the bridges did the task of a translator.

Farewell to the Tower of Babel

The bridges used in the first automation processes were expensive and did not guarantee a definitive solution to the problem, as Gerardo Sánchez, Automation Manager at Trane Mexico, explains: "If someone updated one of the devices and did not notify the translator, there was a risk that the equipment would no longer be useful. Sometimes the manufacturer sold a piece of equipment that had been in the catalog since two years ago and in the end did not work; but there was no way to realize it until the product was acquired and installed."

For this reason, the incorporation of BACnet was relatively easy and fast, and has brought numerous benefits for the entire production chain, especially the end customer who is no longer enslaved to the products of a certain brand. This is confirmed by Rubén Rodríguez Díaz, Regional Account Manager of KMC Controls: "Everyone is on BACnet, because being an open protocol does not depend on a chip".

Rodríguez points out that one of the reasons that allows the continued growth of BACnet is the cost. "When it came out it was more expensive because manufacturers already had their own systems and invested in their developments that were already amortized. But today the cost of implementing BACnet has already been amortized and prices have matched those of products designed with the manufacturer's own protocols, both in the case of hardware and software."

Everything under control

The communication of BACnet-based systems is carried out at different levels, depending on the type of data, the amount of information that is exchanged, etc. Thus, the information that is required to be communicated will depend on the capacity of the system.

It should be noted that most of the systems installed today work under the Master Slave Token Passing, MSTP scheme; that indicates that they have a central or master control, which asks for data from the other devices, known as slaves, through a data network.

According to Rodnei Peres, from the export department of Full Gauge Controls, the disadvantage of these systems is that in case of registering a failure, the entire system will be affected and even stopped until it is resolved. For that reason, he explains, manufacturers and installers are promoting the use of individual interconnected controls. "When the control is individual, the failures only affect a part of the system, so they are more economical."

New technologies

Rodnei Peres is clear in stating that the market for digital controls in Latin America has grown a lot, especially in Spanish-speaking countries, where the speed of market strengthening is much more than double that of Brazil. "Every six months new controls are developed to meet the demand of the region," he said and said that the main interest of customers is energy efficiency.

These new products incorporate new technologies, the cost of which decreases as they become more widespread. One of the main advances today is in the hardware, as baCnet communication was achieved on the web. "It used to be local communication on a computer; today we pass the server to the web and with an Internet Explorer you can access the system from anywhere in the world, "says Rubén Rodríguez.

Thus, the price of the software drops substantially, and costs are saved because it is no longer required to buy a license so that each user can access from their computer, as was the case before.

Many of the installers have expressed concerns about the security of a computer that is web-based. In this regard, Rodríguez confirmed that the system has a good level of protection and that, in addition, access to temperature data or AC conditions in a building is not of interest to hackers.

Another of the outstanding advances is the simplification of the installation process and, above all, of operation. In that sense, says Gerardo Sánchez, "a user with good training and a friendly system for the operation, achieves a greater impact on the consumption of Kw / hour.

To that is added the possibility of having staggered versions of the programs: "Before you had a board for 300 devices or one for 150, and it turns out that sometimes people only had 20 devices and ended up paying for a capacity that they did not use," explains Sánchez. As a solution to this problem, manufacturers have begun to market packages with the same control panel but licensed for 30 devices. In case the user wants to increase the number of systems, he should not change the control or the system, but only buy an extra license to operate more devices.

"With this system, savings of up to 30% in cost are achieved," said the representative of Trane de México.

New technologies

As Rodnei Peres and Gerardo Sánchez pointed out, the development of new systems is continuous in the industry. Today, precisely, many of the efforts of manufacturers are being oriented to the development of IP systems that do not require wiring.

Sánchez explains that these systems are useful in heritage constructions where wiring is impossible because the opening of walls is not allowed to insert the cables. "The wireless technology is simple and economical, the batteries last up to five years and the receiver can move up to 60 meters. It is also suitable for offices that do not move much from place or distribution."

Box

Selecting the right driver

Before purchasing or selecting the control for the appropriate automation system, the experts consulted by ACR LATINOAMÉRICA recommend following the following steps:

1. Determine automation needs: Know how many control points are needed, what type of equipment and systems we are going to integrate, what type of monitoring is needed and what level of security I require for the system.

2. Look for an open protocol: All manufacturers with backup have BACnet. It must be verified that the system and equipment are certified by BTL (BACnet Testing Labs).

3. Compatibility: Verify that the chosen control has flexibility in the inputs and outputs, which are universal.

4. Support: It is important that whoever provides the equipment and software can provide technical assistance. Even the best controller needs it.

5. Operation: The important thing about a digital control is that it can do its job and that the supervisor can access the information. It is vital that it is easy to install and operate.